- Have any questions?

- +86 189 0773 3187

- grindingmill88@gmail.com

- Home

- Ultrafine Grinding Mill

- Ultrafine Grinding Mill

Ultrafine Grinding Mill

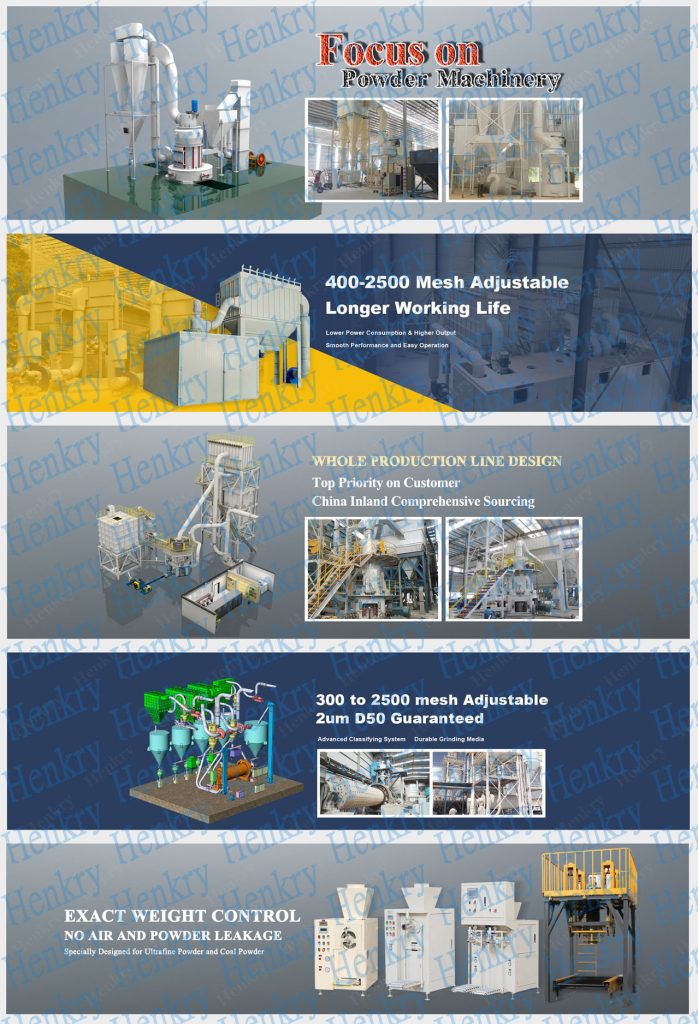

The ultrafine grinding mill is a combination of grinding, impacting and crushing for grinding ultrafine powder. This ultrafine grinding mill has the following features: better fineness, higher output, lower energy consumption, and lower investment. The powder from ultrafine grinding mill has good fineness (D97=3-35um), which can be adjusted according to customer’s requirement to improve the company’s competitiveness.

Structure of Ultrafine Grinding Mill:

Ultrafine grinding mill has the advantages of higher output, low investment and simple grinding technique. The mechanical reaction in the process of grinding is also good to improve powder activity.

The Ultrafine grinding mill has the folllowing components: crusher, elevator, hopper, feeder, classifier, mill, collector, blower and electric control cabinet. And delivery and installation of the whole ultrafine grinding mill system is simple and easy to be completed.

The ultrafine grinding mill is a combination of grinding, impacting and crushing for grinding ultrafine powder. This ultrafine grinding mill has the following features: better fineness, higher output, lower energy consumption, and lower investment. The powder from ultrafine grinding mill has good fineness (D97=3-35um), which can be adjusted according to customer’s requirement to improve the company’s competitiveness.

Special Features of Ultrafine Grinding Mill:

1. Perfect contact between rollers and ring: The arc or curved surface increases their effective working surface and improves the crushing and grinding efficiency. The rollers and rings contact surface and shapes should be consistent and tightly fit, which is good to the production of fine powder.

2. Improved hardness of rollers and rings: this not only guarantees longer working life, but also the powder is not easy to be contaminated.

3. Rotation speed of central shaft can be adjusted according to customer’s requirement.

4. Pulse-jet Collector: 99.99% of the ultrafine powder can be collected, which is also environment-friendly.

5. Constant temperature control system is adopted and the whole design is also improved, so various additives can be put into the mill to improved the application range of powder.

6. High quality casting technology to prolonger the working life of roller and ring.

Technical Data of Micro Powder Grinding Mill:

| Model | SCM800 | SCM1000 | SCM1250 | |||

| Roller Number | 16 | 26 | 26 | |||

| Mill (KW) | 75 | 132 | 160 | |||

| Blower (KW) | 55 | 75 | 90 | |||

| Classifier (KW) | 22 | 30 | 37 | |||

| Output (T/H) | Mesh | KG/H | Mesh | KG/H | Mesh | KG/H |

| 600 | 3200-3500 | 600 | 5000-5800 | 600 | 6500-7200 | |

| 800 | 2500-2800 | 800 | 4000-4500 | 800 | 5500-7000 | |

| 1250 | 1500-1800 | 1250 | 2500-2800 | 1250 | 3500-4000 | |

| 1500 | 1000-1300 | 1500 | 1600-2100 | 1500 | 2500-3000 | |

| 2000 | 650-750 | 2000 | 1100-1600 | 2000 | 1500-2000 | |

| 2500 | 600-650 | 2500 | 900-1300 | 2500 | 110-1500 | |

| Weight (T) | 15 | 23 | 32 | |||